Supply chain networks and business networks enable easier electronic communication, seamless connection and further global reach between business partners. But what are the underlying challenges companies face when choosing a network? This blog article breaks down four major factors to help guide this critical business decision.

Connectivity is everything

In today’s world, almost everything is connected in some way, and our dependency on connected parties is greater than ever. For better or worse, the Covid-19 pandemic has so vividly shown us how these lines are written.

In order to evolve connectivity and make the right strategic choices in a digitalised and connected world, business leaders need to understand the underlying challenges for business networks and supply chain networks. Below are four crucial factors that will help you choose the best network to grow your business. Within each factor, find links to the original articles for further reading.

Factor 1: Network structure

One fundamental aspect is to understand the structure of the network. The vast majority that exist in the context of business and supply chain networks have evolved through gradual connection of one entity to another, growing the network over time. This describes the workings of what is known as a “one-to-one” network.

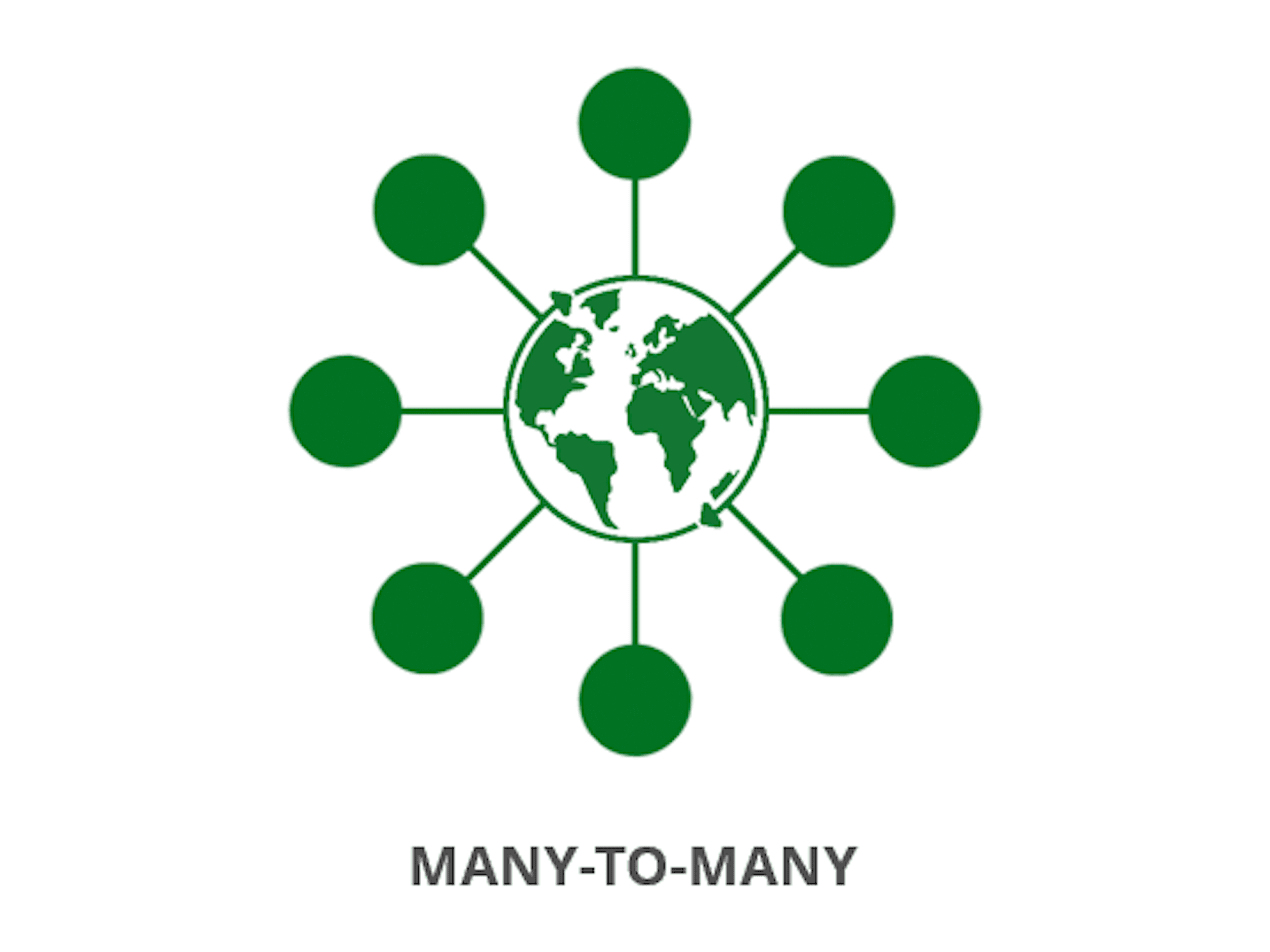

A few vendors have designed their network bottom-up to cater for scalability and controlled structure. Instead of the one-to-one design, this network structure can be referred to as “many-to-many.” See my comparison of the two types of networks to spaghetti bowls and spider webs in this blog.

A network vendor using a scalable, recurring design can establish, commission and grow the network quickly and efficiently. However, the flexibility and scalability are only maintained if the network is strict on standardisation, remains true to its design rules and always keeps long-term perspective in its growth strategy.

Should you opt for the one-to-one or many-to-many structure? If customisation is of greater importance than scalability and your focus is short-term, one-to-one might work for you. Are you striving for global digitalisation, process harmonisation and long-term transaction cost control? Then the many-to-many option is the more attractive one. Regardless, before making your final decision, make sure you really understand the underlying structure of the network you are considering connecting to.

Figure 1: A one-to-one network structure requires many different connections between your company, buyers, suppliers, government authorities and other networks.

Figure 2: A many-to-many network connects your business to all its business partners and government authorities through a single connection to the network.

Factor 2: Network ecosystem

When choosing business or supply chain networks, how can you effectively assess if it will work both short-term and long-term for your company? The extent and reach of a network’s ecosystem should play a significant role in your analysis.

When network operators or application providers approach clients, they typically begin by addressing specific needs of one area or department. The result is an unchecked development of several different types of networks with varying characteristics that internal IT usually ends up managing via customised integration engines. The short-term problems are often negligible and thus overlooked, but long-term they emerge as operational risk factors and high maintenance costs at questionable returns. You will end up with siloed network problems, paying the price in real dollars for many years to come.

The key is to employ a holistic digitalisation strategy. Once you have worked through such a strategy and identified the needs of your production, logistics, services, sourcing, finance, delivery and sales departments, you will be better equipped to make informed decisions.

Factor 3: Network integrity

Perhaps one of the most critical aspects to consider when selecting a business and/or supply chain network is how they will protect the integrity of one of the highest valued commodities in the digital world: data. It is a double-edged sword; you want access to data within and beyond your own domain but are likely unwilling to share your data with others. As most organisations think the same, you need to carefully consider how you want your network to handle your data.

For instance, not allowing the network operator to use anonymised data for analytics or diagnostic purposes may actually be counterproductive for your company and your operations. In the long run, you will lose your competitive edge and become sub-par in the market space.

Another aspect which you should consider is collaboration. To reap the benefits of a network, especially supply chain networks, you want to be able to exchange data and information with your business partners, i.e. customers and suppliers. In this context, anonymised data won’t do the trick. The content of that data is of little to no value to the individual transaction in the network. So, you need to categorise data and levels of integrity.

Last but not least in the context of network integrity is regulatory compliance. Negligence of regulatory compliance can pose a real revenue loss risk in your business continuity plans. Regulatory non-compliance is currently mostly a B2G issue, but this is rapidly changing to also affect B2B and B2C transactions both locally and globally.

Factor 4: Legal control of the network

Almost all business and supply chain networks did not just emerge out of the blue. They have grown gradually and adopted different technologies, in many cases, having grown through mergers and acquisitions. This means that even within a certain network, legal and security structures can vary significantly.

Consider that supply chains are at best varied when it comes to IT maturity. You will likely find very or reasonably mature and modern IT environments among the larger buyers, suppliers and/or service providers. But they usually use a variety of networks and in many cases their own point-to-point connections, which may or may not hold up to the highest standards.

We also need to acknowledge the fact that many companies are smaller. Even if they are sheltered under large and well-trusted brands, they have rudimentary IT infrastructures. It would be naïve to claim that they are resistant to security breaches or that they are connected in ways that are easy to overlook and control from a legal perspective. Read more about the repercussions of such loosely held networks.

The business risk emanating from security and legal risk in a network context should not be neglected. The importance of a structured, compliant and legally controlled network in your digitalisation strategy cannot be emphasised enough.

Take the plunge

There’s no doubt that finding the right business or supply chain network will improve the way you operate. With end-to-end oversight and control of the flow of goods and communication, your company and business relationships will flourish. So, begin your search with the above four factors in mind, ask the right questions to fully understand your options, and jump in.

Find your solution today

Stay in the loop with our newsletter

Get in touch

Interested in getting started or learning more? Leave your contact details here and we will reach out to you!